Innovative Piping Trends for Modern Construction Projects

In today’s dynamic construction landscape, adopting state-of-the-art piping solutions can be a game-changer for developers and contractors seeking improved efficiency, project longevity, and overall sustainability. As the industry faces mounting pressure to minimize operational costs, shorten project timelines, and meet stringent environmental requirements, exploring leading-edge advancements in piping technology becomes essential. Implementing modern solutions allows construction professionals to enhance durability, reduce both upfront and life-cycle costs, and promote environmental responsibility, appealing to eco-conscious clients and regulators alike. For those seeking proven, reliable materials and world-class service partners, Cruco Mill & Industrial Supply offers an array of essential resources, technical expertise, and innovative products to help keep projects ahead of the curve.

The integration of groundbreaking technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and advanced digital modeling, has fundamentally transformed traditional piping systems, making them more intelligent and capable than ever before. These sophisticated technologies enable construction and facility management teams to remotely monitor system health, diagnose emerging issues quickly, and address challenges proactively, minimizing costly interruptions. Simultaneously, investment in advanced piping materials, such as composites and polymers, coupled with widespread adoption of prefabrication and sustainable manufacturing practices, is reshaping what’s possible in plumbing and piping. Modern piping systems are now required to be not only robust and versatile but also highly adaptable to shifting project demands and future expansions, enabling the industry to meet expectations for infrastructure longevity and ecological stewardship.

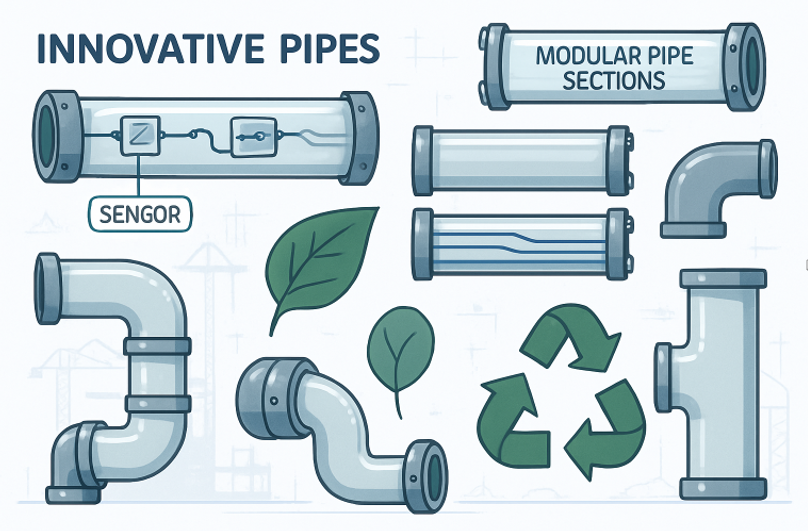

Smart Piping Systems: IoT and AI Integration

One of the most impactful developments in contemporary piping is the seamless combination of the Internet of Things (IoT) and artificial intelligence (AI). By embedding smart sensors directly within piping networks, systems can now constantly gather and transmit granular data regarding flow rates, pressure levels, water quality, and temperature variations. This steady stream of data is analyzed by AI-powered platforms that can instantly detect irregularities or deviations from baseline operation, quickly alerting operators to take action before minor issues escalate into major failures. Real-time diagnostics of this nature significantly reduce the risks of costly ruptures, undetected leaks, and resulting infrastructure damage, thereby preserving both commercial assets and operational uptime. In large-scale commercial and industrial projects, these innovations aren’t just improving system performance—they’re also setting new standards for safety, risk mitigation, and ongoing efficiency.

Predictive maintenance, enabled by these intelligent technologies, gives facility managers an unprecedented ability to craft data-driven, strategic maintenance schedules tailored to real-world operation needs. Instead of relying on antiquated, interval-based methods or only reacting to failures once they occur, teams can now anticipate wear patterns and intervene proactively, minimizing the frequency and costs associated with emergency repairs. This proactive approach not only extends the useful life of expensive piping infrastructure but also lowers operational expenditures over the system’s lifecycle. Some AI-driven maintenance solutions even simulate system behavior under different scenarios, identifying potential failure modes long before any physical degradation becomes apparent, giving operators valuable time to implement solutions and prevent downtime.

Advanced Materials Enhancing Durability and Efficiency

The piping industry is witnessing a significant and rapid shift away from traditional metals, such as copper or steel, toward cutting-edge composite and polymer-based materials. Composite pipes, typically constructed from a combination of reinforced fibers (like fiberglass or carbon fiber) and high-performance resins, perform exceptionally well in environments that are corrosive, high-pressure, or otherwise demanding. These modern pipes offer outstanding resistance to both internal and external corrosion, can withstand exposure to aggressive chemicals, and are up to 70% lighter than their steel counterparts, making transportation and installation easier, faster, and less labor-intensive.

The adoption of polyethylene-based materials, such as cross-linked polyethylene (PEX) and high-density polyethylene (HDPE), is also accelerating across all industries for similar reasons. These materials are highly valued not only for their flexibility and inherent chemical resistance but also for enabling faster installation processes with fewer joints and fittings required. This means fewer potential leak points, lower maintenance needs, and faster construction schedules. Today, PEX and HDPE are not just mainstays in residential plumbing—they are also increasingly found in municipal water and sewer infrastructure, as well as large-scale industrial projects, due to their robust performance and environmentally responsible profile.

Prefabrication and Modular Design

Prefabrication has ushered in a new era of consistency, efficiency, and reliability in piping installation. When pipe spools, assemblies, or even entire sections are constructed off-site in tightly controlled factory environments, it’s possible to achieve far higher levels of quality control, precision, and consistency than with traditional on-site methods. Factory fabrication benefits from accurate digital modeling and advanced production technologies, virtually eliminating common installation imperfections and accelerating project timelines. After production, these prefabricated modules are transported directly to worksites, where they can be rapidly installed and connected with minimal disruption to other aspects of ongoing construction.

Modular piping designs expand on these benefits by allowing builders to scale, customize, or even reconfigure systems on demand. Rather than being locked into static infrastructure, project teams can adapt to unexpected requirements, shifts in building occupancy, or changes in regulatory codes with ease, simply by swapping out modules or updating layouts. For commercial developments, industrial facilities, and institutional campuses, this flexibility translates to lower long-term costs and superior returns on investment, as the system can evolve in tandem with the broader needs of the space.

Eco-Friendly Materials and Manufacturing Techniques

Environmental stewardship and sustainability are now top priorities across the entire construction sector—and piping manufacturers are responding by developing and utilizing recyclable and biodegradable materials wherever possible. High-density polyethylene (HDPE) and PEX pipes both offer excellent mechanical performance and flexibility; equally important is their low environmental impact throughout the product’s lifecycle. Many manufacturers have implemented eco-friendly operations by employing renewable energy sources, adopting resource-efficient manufacturing processes (such as additive manufacturing and closed-loop recycling), and minimizing waste at every stage of production. Some companies even go a step further with take-back programs, recycling spent pipes into new products to ensure a more circular economy and a reduced carbon footprint. As the demand for green building certifications grows, these sustainable practices are quickly becoming the standard for responsible construction projects.

See also: Innovative Applications of License Plate Recognition Technology

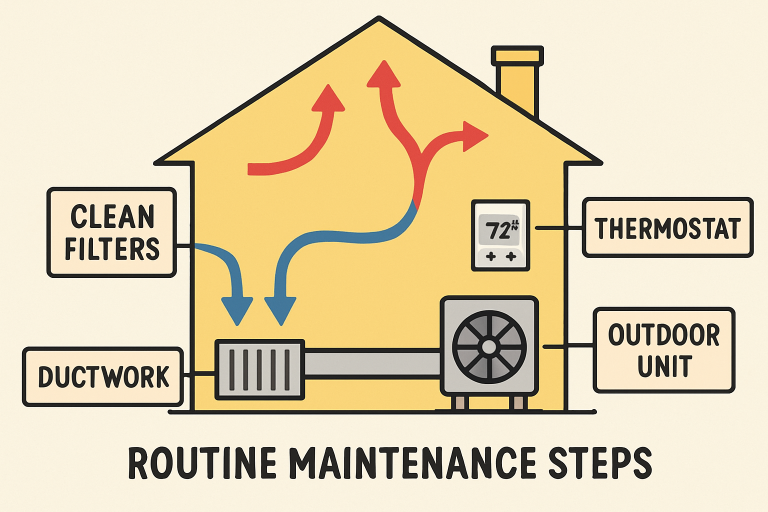

Robotics and Automation in Piping Maintenance

Robotics and automation are transforming the way inspections and maintenance activities are performed across various piping installations. Small, highly maneuverable robots equipped with cutting-edge cameras, ultrasonic testing tools, and even laser scanners can navigate deep into vast, complex piping networks to identify cracks, blockages, or areas of corrosion before they threaten system integrity. By handling visually or physically hazardous inspections from within the lines, these robots eliminate the need for human inspectors to enter dangerous, confined spaces—dramatically increasing worker safety while also reducing liability concerns for employers. Automated systems are also capable of performing some in-situ repairs without requiring major system shutdowns, minimizing costly downtime for property owners and facility managers.

Digital Twin Technology for Piping Systems

The rise of digital twin technology is opening up unprecedented possibilities for planning, monitoring, and optimizing piping systems. With a digital twin—a detailed, real-time virtual replica of a physical system—engineers can model new designs, test multiple maintenance strategies, and monitor various system parameters under real-world conditions without risking damage to physical infrastructure. This innovative approach enables the detection of potential issues, such as flow disruptions, pressure differentials, or developing leaks, virtually, allowing solutions to be enacted before problems occur in the field. By leveraging historical and real-time data, teams can refine their strategies, enhance system resilience, and manage maintenance schedules more effectively, all while keeping risk and costs under control throughout the project’s lifespan.

Conclusion

By embracing innovation in advanced materials, intelligent digital monitoring, robotics, prefabricated modular assemblies, and eco-friendly manufacturing practices, today’s construction professionals can deliver piping solutions that maximize performance, ensure the highest levels of safety, and promote true environmental responsibility. Staying informed and proactive in applying these transformative trends empowers teams to deliver projects that are not only technically superior but also better equipped to meet rapidly evolving industry standards, client expectations, and regulatory frameworks.